How to Test and Maintain Commercial-Grade GFCI and AFCI Outlets

In commercial electrical systems, safety is paramount, and outlets designed to protect against electrical hazards play a significant role. Ground Fault Circuit Interrupter (GFCI) and Arc Fault Circuit Interrupter (AFCI) outlets are essential components that provide extra protection to both people and property. GFCIs are designed to protect against ground faults, while AFCIs prevent electrical fires caused by arcing conditions. Regular testing and maintenance of these outlets are crucial to ensure they perform optimally, and this is where professional commercial electrical services are invaluable. In this article, we will discuss how to test and maintain commercial-grade GFCI and AFCI outlets, focusing on the importance of these devices and the proper procedures for upkeep.

Understanding GFCI and AFCI Outlets

Before diving into testing and maintenance procedures, it’s important to understand the roles of GFCI and AFCI outlets in a commercial setting.

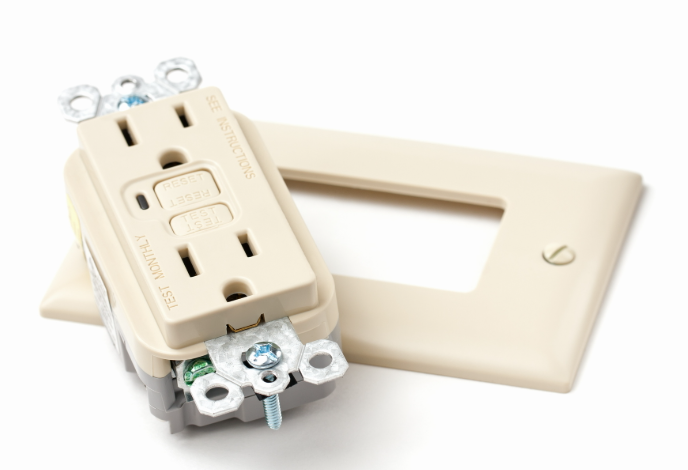

GFCI Outlets: These outlets are designed to prevent electrical shock by detecting ground faults. A ground fault occurs when electricity flows along an unintended path, such as through water or a person. If a GFCI detects a difference in the current between the hot and neutral wires (which indicates a ground fault), it will instantly shut off the power to the outlet, reducing the risk of injury or death.

AFCI Outlets: AFCIs are designed to detect arc faults, which are unintended electrical discharges that can cause fires. Arc faults typically occur when wiring is damaged, loose, or frayed, creating a condition where electricity jumps or arcs between wires. AFCIs detect these irregularities and quickly cut power to prevent fires.

Both of these devices are critical for ensuring the safety of a commercial electrical system, particularly in environments where large amounts of equipment are used, or there is a higher risk of electrical accidents.

Why Testing and Maintenance Are Important

Over time, GFCI and AFCI outlets can wear out due to normal usage or environmental factors, such as moisture or dust. Regular testing ensures that they are functioning properly, and maintenance helps extend their lifespan. Failure to maintain these outlets can lead to undetected hazards, such as electrical shocks or fires. A professional commercial electrician can help ensure that these devices are working as intended, maintaining the safety of the commercial space.

Read also: AI Face Swap Technology and Its Potential in Digital Art

How to Test GFCI Outlets

Testing a GFCI outlet is straightforward, but it is essential to follow the correct procedure to ensure proper functionality.

1. Manual Test Button

Most commercial-grade GFCI outlets come with a built-in test button. This is the easiest way to test the outlet’s functionality. Here’s how to test it:

- Step 1: Plug a lamp or a small appliance into the outlet to confirm that it is working correctly.

- Step 2: Press the “Test” button on the GFCI outlet. This should immediately cut the power to the outlet, and the appliance should turn off.

- Step 3: Press the “Reset” button to restore power. The appliance should turn back on.

By pressing the test button regularly, you ensure that the GFCI is capable of detecting ground faults and cutting the power when necessary. If the power does not turn off after pressing the test button, the outlet is likely defective and should be replaced by a commercial electrician.

2. Using a GFCI Tester

A GFCI tester is a small, handheld device that can be plugged into the outlet to check its functionality. To use a GFCI tester:

- Plug the tester into the outlet.

- The tester will indicate whether the GFCI is wired correctly and if it is functioning properly.

- Follow the instructions on the tester to interpret the results. A proper reading indicates the outlet is safe to use.

GFCI testers are widely available and can be used by anyone, including commercial electricians, to perform basic checks.

How to Test AFCI Outlets

Testing AFCI outlets is slightly different from GFCI outlets but equally important. Here’s how to test AFCI outlets:

1. Manual Test Button

Just like GFCI outlets, many AFCI outlets also come with a test button. To test an AFCI outlet using the manual test button:

- Step 1: Plug a small appliance into the outlet to verify that the outlet is supplying power.

- Step 2: Press the “Test” button on the AFCI outlet. The power should immediately turn off, indicating that the AFCI has detected a potential arc fault.

- Step 3: Press the “Reset” button to restore power.

If the outlet does not trip when pressing the test button, it indicates a potential malfunction, and the outlet should be inspected or replaced by a commercial electrician.

2. AFCI Circuit Breaker Test

In some cases, AFCIs are integrated into circuit breakers rather than outlets. These breakers often have a “Test” button located on the breaker itself. Testing the AFCI breaker works similarly to testing the outlet:

- Step 1: Press the “Test” button on the breaker.

- Step 2: The breaker should trip, cutting the power to the circuit. If the breaker does not trip, it may need to be replaced.

It is important to check both outlets and circuit breakers regularly to ensure protection against arc faults.

Maintenance of GFCI and AFCI Outlets

While testing is important, commercial electrical services recommend regular maintenance is also crucial to ensure the continued functionality of GFCI and AFCI outlets.

1. Clean the Outlets

Over time, dust, dirt, and moisture can accumulate on outlets, leading to performance issues. A commercial electrician will clean the outlet faces and surrounding areas regularly to maintain optimal functionality. Cleaning involves using a dry cloth to wipe away any dust or debris. For more stubborn dirt, a lightly dampened cloth can be used, but it is important to avoid getting moisture inside the outlet.

2. Inspect for Physical Damage

Regularly inspect outlets for signs of physical damage, such as cracks or burn marks. Damaged outlets should be replaced immediately by a commercial electrician, as they could pose an electrical hazard. If the outlet is warm to the touch or showing signs of wear, it may indicate an internal issue that requires professional attention.

3. Check for Loose Connections

Loose wiring connections are a common cause of outlet failure. If an outlet isn’t working correctly, the wiring may have come loose. A commercial electrician can check the wiring connections, tighten any loose connections, and replace any damaged wiring to ensure safety.

4. Test Outlets After Power Surges

In commercial settings, power surges caused by lightning or equipment malfunctions can damage GFCI and AFCI outlets. After a significant power surge, it is advisable to test all GFCI and AFCI outlets to ensure they are still functioning correctly. If an outlet doesn’t reset after a power surge, it may need to be replaced.

Conclusion

Regular testing and maintenance of commercial-grade GFCI and AFCI outlets are essential for the safety and reliability of electrical systems in commercial buildings. These outlets provide critical protection against electrical shocks and fires, and ensuring they are in good working condition is key to preventing accidents and ensuring business continuity. By conducting regular tests, cleaning the outlets, inspecting for damage, and addressing any issues promptly, commercial electrical services can help keep a building’s electrical system running smoothly and safely. Whether you are a business owner or a facility manager, working with qualified commercial electricians to maintain these outlets will help protect your employees, property, and equipment from potential hazards.